We travel only 20 minutes just down the hill from our village of Castelvetro to the property known as Hombre, one of the most significant Parmigaino producers in all of Italy. We are taken on a guided tour of the dairy, These comments from Wikipedia sum it up perfectly;

It is named after the producing areas, which comprise the Provinces of Parma, Reggio Emilia, Bologna (only the area to the west of the river Reno), Modena (all in Emilia-Romagna), and Mantova (in Lombardia, but only the area to the south of river Po), Italy. Under Italian law, only cheese produced in these provinces may be labelled “Parmigiano-Reggiano”, and European law classifies the name, as well as the translation “Parmesan”, as a protected designation of origin. Parmigiano is the Italian adjective for Parma and Reggiano that for Reggio Emilia. Parmigiano-Reggiano is made from raw cow’s milk.

The whole milk of the morning milking is mixed with the naturally skimmed milk (which is made by holding milk in large shallow tanks to allow the cream to separate) of the previous evening’s milking, resulting in a part skim mixture. This mixture is pumped into copper-lined vats (copper heats and cools quickly). Starter whey (containing a mixture of certain thermophilic lactic acid bacteria) is added, and the temperature is raised to 33-35 °C (91-95 °F). Calf rennet is added, and the mixture is left to curdle for 10–12 minutes.

The curd is then broken up mechanically into small pieces (around the size of rice grains). The temperature is then raised to 55 °C (131 °F) with careful control by the cheese-maker. The curd is left to settle for 45–60 minutes. The compacted curd is collected in a piece of muslin before being divided in two and placed in molds. There is 1100 L (291 US gallons or 250 imperial gallons) of milk per vat, producing two cheeses each. The curd making up each wheel at this point weighs around 45 kg (100 lb). The remaining whey in the vat was traditionally used to feed the pigs from which “Prosciutto di Parma” (cured Parma ham) was produced. The barns for these animals were usually just a few yards away from the cheese production.

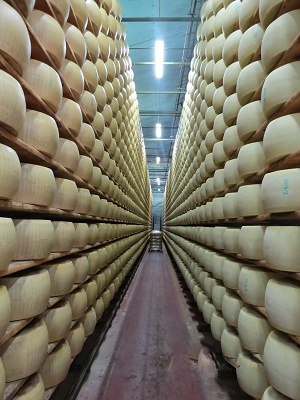

The cheese is put into a stainless steel, round form that is pulled tight with a spring-powered buckle so the cheese retains its wheel shape. After a day or two, the buckle is released and a plastic belt imprinted numerous times with the Parmigiano-Reggiano name, the plant’s number, and month and year of production is put around the cheese and the metal form is buckled tight again. The imprints take hold on the rind of the cheese in about a day and the wheel is then put into a brine bath to absorb salt for 20–25 days. After brining, the wheels are then transferred to the aging rooms in the plant for 12 months. Each cheese is placed on wooden shelves that can be 24 cheeses high by 90 cheeses long or about 4,000 total wheels per aisle. Each cheese and the shelf underneath it is then cleaned manually or robotically every seven days.

At 12 months, the Consorzio Parmigiano-Reggiano inspects every cheese. The cheese is tested by a master grader whose only instruments are a hammer and his ear. By tapping the wheel at various points, he can identify undesirable cracks and voids within the wheel. Those cheeses that pass the test are then heat branded on the rind with the Consorzio’s logo.

Those that do not pass the test used to have their rinds marked with lines or crosses all the way around to inform consumers that they are not getting top-quality Parmigiano-Reggiano; more recent practices simply have these lesser rinds stripped of all markings.

Its worthwhile going to Wikipedia to read the story of this chap , Umberto Panini. The Umberto Panini Classic Car Collection is one of the most fascinating exhibitions dedicated to Maserati. Cars that have made Maserati history and that have been lovingly gathered over the years are housed in a typical building in Cittanova, Modena.

Originally the brainchild of the Maserati brothers and expanded by Omar Orsi, the collection has remained more or less intact to the present day. It is now run by West (a company owned by the Panini family) and includes 23 cars on display and three that are currently undergoing restoration.

Next a visit to Consorzio del Prosciutto to see the process of the amazing Prosciutto from this area.

After experiencing the end product of this amazing cheese & proscuitto, and wandering through the car museum we depart via the tree lined driveway, and travel only 10 minutes to find our next adventure.

This time with the Pedroni family and their prized Balsamic Vinegar of Modena DOP.

Balsamics tasted for entree main and dessert. Incredible.

Their other specialty, Grappa, was also on the agenda

We are shown the process with the grapes coming in whilst we were there, the heating and skin extraction, through to the barrel maturation.

Then we dine with the Pedroni’s enjoying a selection of local anti Pasta’s, their own wines and a selection from the region followed by local Grappa.

For more information on how you can experience this personalised type of tour in Italy go to wineandfoodtraveller.com Most of the product highlighted in this series is available from Benfatta Fine Foods in Australia.

For more information on how you can experience this personalised type of tour in Italy go to wineandfoodtraveller.com Most of the product highlighted in this series is available from Benfatta Fine Foods in Australia.